Luxury bed and breakfast on the Isle of Wight

Looking to retreat and be nestled deep in nature? Our lovely Isle of Wight escape touches the hearts of all who visit. We have the perfect getaway venue for couples, residential groups, families or individuals looking for a warm welcome in a rural setting and those looking for somewhere special to celebrate an important occasion.

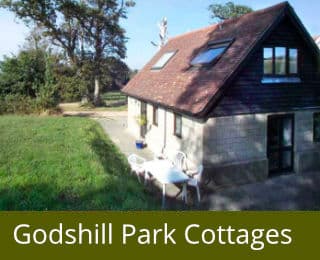

During 2018 we converted a disused barn into additional bespoke luxury self catering Isle of Wight accommodation that sleeps 11. With a dining room opening its doors to the abundant hillside, a massage treatment room and five high-quality en suite bedrooms, it’s perfect for large families and groups. The south facing sitting room in the barn has comfy sofas and a wood burning stove. Godshill Park Barn is a luxury bed and breakfast whilst our cottages are self catering accommodation.

We, Kathy and Mark, have been welcoming guests at Godshill Park Farm for over 20 years. Quickly we learned how to create warm, comfortable, relaxing accommodation with good food. Godshill Park Barn is a sympathetic blend of the traditional and the innovative, a spectacular example of modern rural architecture in an Area of Outstanding Natural Beauty.

Isle of Wight barn holidays set on our working livestock farm bring you to a hamlet near the picturesque village of Godshill in one of the most beautiful parts of the island. Peace and tranquillity are guaranteed here in our little part of the IOW.

We offer a range of massages and other therapeutic treatments all year round – click here for further details. Plus, we now have an Electric Vehicle charging point on site. Wifi is available across the whole site.

The farm specialises in supporting rare native breeds. Castlemilk moorit and Boreray sheep, Dexter cattle, horses, miniature ponies, llamas and alpacas graze the fields. Home grown boreray and moorit fleece is woven into blankets, blinds, throws and cushions to decorate walls and sofas in keeping with our location.

Situated at a crossroads of bridleways and footpaths, Godshill Park Barn guests can walk, run or cycle through ancient woodlands or up over the downs for panoramic views of the island, English Channel and Solent. You are never far from a beach on the Isle of Wight, we have plenty of beautiful spots for holiday beach days.

The 20 minute ferry journey across to the Isle of Wight from the mainland also allows for precious moments of decompression; a wonderful restorative start for your visit. We offer assistance with booking ferries to and from the island if needed.

The Taverners pub, Griffin pub and Cook & Baker restaurant are just a short walk away together with Godshill Model Village, medieval church, quaint shops and tea rooms in the village. We are centrally located on IOW being 6 miles south of Newport, 4 miles to the west of Shanklin and 4 miles north of Ventnor. There’s lots to do on the Isle of Wight and being a small island, it’s never too far away.

Fishing in our private lake on the farm is exclusively for our guests and we regularly host yoga and wellbeing retreats here in the barn during the Autumn and Winter months.

For the adventurous, our unique accommodation named ‘The Hut’ may fit the bill. The private hot shower and kitchenette are only 35m away.

The Barn can also be hired as a complete self catering property – either for a retreat or family holiday.

There is a bus stop at the end of the drive where you can catch a bus to Newport or to Shanklin and beyond. The nearest train station is in Shanklin which connects with Ryde pierhead and the ferry to Portsmouth Harbour.

We love that the absence of light pollution gives clear starlit skies here at Godshill Park Farm.

For retreat and events details please click here.

Our accessibility statement can be found at

https://www.accessibilityguides.org/content/godshill-park-barn

Godshill Park Barn has been developed into a yoga retreat with part funding from the European Agricultural Fund for Rural Development.